Planning and targeting fertiliser application

The rising costs of chemical fertiliser application, not only considering the price of fertiliser, but also increasing fuel prices, have made it vital to plan the application of both organic manures and chemical fertiliser to ensure maximum efficiency, which in turn can have a positive environmental impact.

Soil Sampling

The first step in planning the application of fertiliser is soil sampling. This allows you to determine the current soil pH and nutrient status; soil sampling kits and soil augers are available through your local DAERA Direct Offices, simply phone or email to order.

Soil analysis should be carried out every 4 years; this could be a whole farm approach every 4 years, or sampling 25% of the farm each year.

Sampling should be done between November – February, at least 3 months after fertiliser application and should be completed before any slurry or fertiliser is applied.

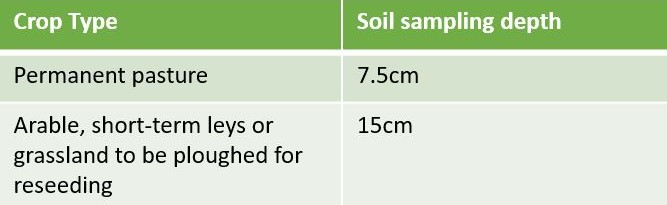

Sampling should be carried out to the correct depth as shown in Table 1 below.

In order to ensure accurate soil analysis results, a minimum of 25 samples should be taken from a maximum 4ha area. Soil sampling can be carried out for each field or block of land under the same cropping regime. To ensure accurate and representative sample results, you should walk in an ‘W’ pattern across the area to obtain a random sample, avoiding gateways, troughs and headlands.

See below a video guide to soil sampling by CAFRE Technologist, Andrew Thompson

Planning fertiliser application

Soil analysis results are required to create a fertilisation plan. Application of organic manures and fertilisers should be targeted at low nutrient index areas, where they will provide the most benefit to the crop, while reducing the likelihood of leaching or runoff. Targeted application to silage or grazing fields with low index soils can be beneficial, remember you may not need to apply fertiliser to high index soils where sufficient nutrients are available. Creating a plan to maximise production from the most productive land will increase yields.

Creating a fertilisation plan using the CAFRE Crop Nutrient Calculator will help to ensure that crop nutrient requirement is met, but not exceeded. Therefore, improving the efficiency of fertiliser applied, while reducing the likelihood of negative environmental impacts such as runoff of excess nutrients into waterways.

With the significant increase in fertiliser prices, it is imperative to maximise crop response from fertiliser application through good management practices such as the creation of a fertilisation plan and correcting soil pH to ensure maximum fertiliser utilisation.

Importance of soil fertility and pH

Soil pH plays a major role when considering nutrient availability and soil fertility. Maintaining optimum soil pH will increase the microbiological activity within the soil, resulting in better soil nutrient recycling and release, in turn having a positive impact on crop growth and fertiliser utilisation.

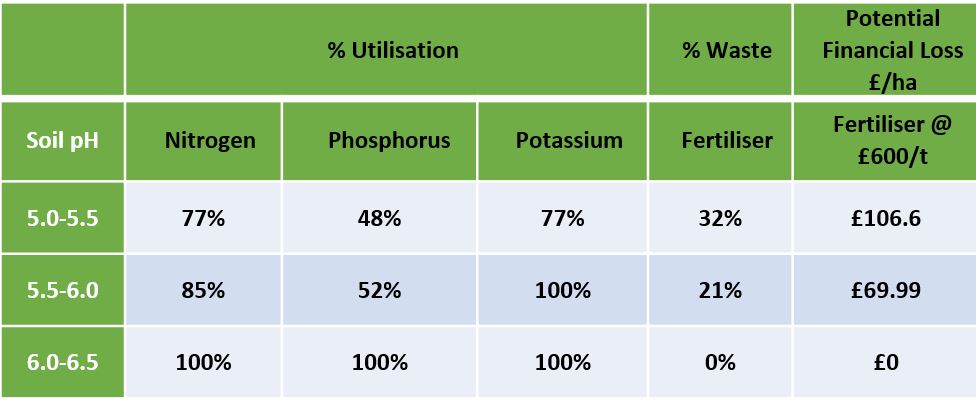

Figure 1 below outlines how increasing from soil pH 5.0 to pH 6.0-6.5, enhances fertiliser utilisation and reduces the percentage of fertiliser wasted. With rising fertiliser prices, electricity and fuel prices, ensuring the maximum fertiliser utilisation is not only of environmental importance, but also has an impact on business profits. Therefore, it is important to correct pH by applying lime.

Source: Teagasc/DAERA 2017, based on applying 150kgN/ha of 27.4.4.

Soil Temperature

Crop growth does not begin until the soil temperature reaches 5˚C and above in spring. By measuring soil temperature before applying slurry, manure or chemical fertiliser, this will help to ensure that the nutrients being applied will be absorbed and utilised by the plant.

Where nutrients are applied to land before optimum soil temperature conditions have been reached, they will provide little to no benefit to the crop, therefore having a negative impact on business profits and could potentially be detrimental to water quality due to the increased risk of leaching and surface runoff.

Why use Low Emission Slurry Spreading Equipment (LESSE)

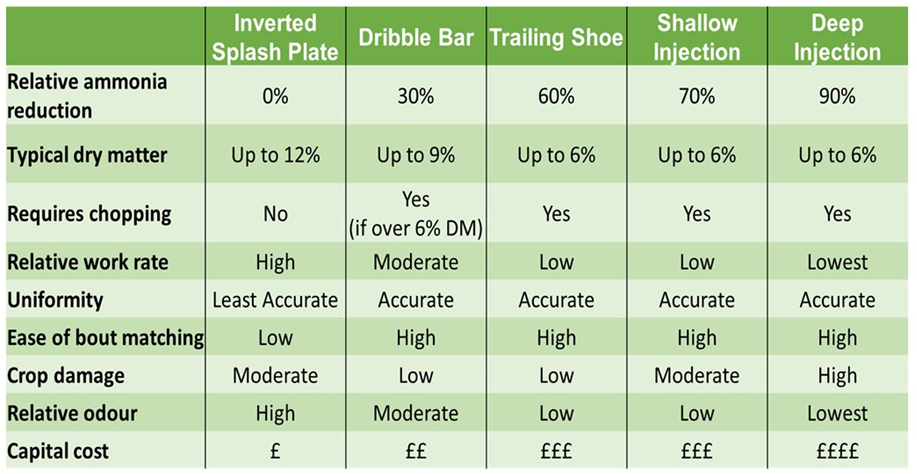

The use of LESSE can impact nutrient utilisation and uptake. Figure 2 provides a comparison of LESSE application systems for a range of factors from ammonia reduction to capital cost. LESSE can be beneficial when targeting the application of slurry as, for example, the dribble bar system reduces ammonia emissions by up to 30%, and is uniform in spreading with minimal crop damage. Reducing the amount of nitrogen lost as ammonia will positively impact the nutrient quantity of slurry and therefore increases the amount of nutrients being delivered directly to the crop, opposed to being lost to the atmosphere.

Maintenance and Calibration of Equipment

In addition, regular maintenance and calibration of slurry and fertiliser spreading equipment is essential to ensure accurate application, Global Positioning System (GPS) and variable rate application can also improve slurry and fertiliser application and usage efficiency while reducing potential runoff of nutrients.

Maintenance checks of machinery and equipment, such as checking slurry tankers for weld deterioration or corrosion, checking tyre pressure and condition, ensuring wheel nuts/studs are torqued to the manufacturers recommended settings. Carrying out checks on the Power Take-Off (PTO) shaft and ensure that the guard is the correct size and length, made to a recognised standard and is not damaged before use. When using LESSE it is also important to check for blocked pipes or hoses before using equipment, as a blocked or damaged hose could lead to inaccurate application. Maintenance checks should be carried out prior to slurry application.

Regular maintenance of machinery and calibration are important to maximise nutrient uptake by applying the correct amount of slurry. Where machinery is not calibrated and too much slurry is applied, valuable nutrients are wasted, this can increase the risk of runoff into waterways, having a negative environmental impact, and also wasting valuable nutrients. Alternatively, where too little is applied, growth will be impaired, meaning that a larger quantity of chemical fertiliser may be required to meet crop nutrient requirement.

Benefits of targeting the application of slurry and chemical fertiliser

Taking into consideration the results of soil analysis, soil temperature, and creating a fertilisation plan, this allows for the targeted application of both slurry and chemical fertiliser.

Targeting the application of slurry will maximise the utilisation of nutrients in low index areas where it will provide the most benefit. Where slurry and manure application is targeted to maximise growth, ‘topping-up’ with chemical fertiliser to meet crop nutrient requirement will be reduced, potentially reducing the quantity of chemical fertiliser required.

Slurry Analysis

When considering targeting the application of slurry, there are cost saving benefits where slurry analysis is carried out. This can determine the nutrient content of manure and slurry on individual farms, potentially reducing the requirement for chemical fertiliser. Knowledge of the exact nutrient content of the slurry applied allows for more specific planning based on crop nutrient requirement and soil analysis results. For slurry analysis, sampling bottles and request forms are available through your local DAERA Direct office.

Key Message

Using the CAFRE Crop Nutrient Calculator to create a fertilisation plan can assist you in maximising the utilisation of nutrient supplied from slurry and manure. By planning the application of nutrients based on soil analysis results, correcting pH and using a targeted approach to supply nutrients, this can potentially reduce overall spend on chemical fertiliser, while making use of the nutrients in slurry.