Replacement Heifer Building

Building specification

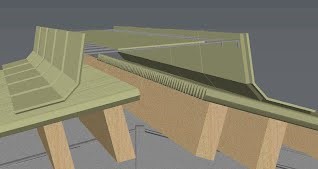

The building is constructed from a portal frame structure with external dimensions 38.4m x 26.3m, eaves height of 5.0m and roof slope 19 degrees. The total footprint of the building is 1,010m2. The specification of the building includes the following features:

- 78 No. heifer cubicles

- 1 No. central feed passage

- 6 No. water troughs

- 1 No. stock bull pen with service and exercise facilities

- 2 No. sick animal pens

- 1 No. storage facility for feed used daily

- Cattle handling facilities with transport loading ramp

- Provision for development of automatic electronic identification and weighing

- Ammonia emission reduction technologies integrated into the waste management system

- Biosecurity provisions to exclude access by disease transmitting vermin

- Ventilation and lighting systems to optimise health and productivity

Cladding

The roof cladding is corrugated fiber reinforced cement sheeting and translucent sheets to provide 15% natural light. The gable cladding is box profiled steel sheeting in juniper green, colour matching the new dairy unit. The eaves cladding is spaced timber cladding.

Ventilation

The building is naturally ventilated with a protected open ridge outlet along the length of the building with a clear outlet width of 163mm to give an outlet area per 400 kg animal of 0.063m2. Total clear ventilation outlet 6.3 m2. The ridge is bird proofed. Inlet ventilation is provided through spaced board cladding along the East side of the building to give an inlet ventilation area per animal of 0.125m2. The total ventilation inlet area along each eaves of the building is at least 6.3 m2. Inlet ventilation along the West side eaves is provided through the recently constructed silo side cladding.

Slurry handling system

The slurry handling system within the building has been designed to take account of the following:

- Hoof grip to improve animal welfare and facilitate oestrus expression

- Ammonia volatilisation from floor surfaces and slurry tanks

- Slurry production from 1-2 year old heifers of 0.18 m3 per animal per week

- Dirty water from internal surface washing adding 0% to slurry volume

- Slurry storage outside the building to avoid the risk of student, staff and animal exposure to slurry gas during mixing

- Storage capacity of 50 m3 to provide 2-3 weeks to allow for pump repair in the event of breakdown

- External slurry mixing and pumping to centrally located slurry stores

Slurry tanks and channels

A 40 m2 slurry tank and channels has been designed within the building to store slurry from an automatic scraper system. Dimensions of the tank and channels are detailed in Table 1.

Table 1. Slurry tanks and channels

| Tank/Channel | Length (m) | Width (m) | Depth (m) | *Capacity (m3) | Surface area (m2) |

|---|---|---|---|---|---|

| 1 | 8 | 5 | 2.4 | 96 | 40 |

| 2 | 35 | 1.0 | 1.0 | 35 | 35 |

| 3 | 13 | 1.0 | 1.0 | 13 | 13 |

*Capacity after deducting 0.3m freeboard and allowance for channel

The slurry tank, (Tank 1) is sized to provide 2-3 weeks slurry and dirty water storage capacity. The tank is positioned outside the north end of the building. The tank is be provided with an electrically powered mixing and transfer pump operated automatically and controlled by a level sensor. Slurry is pumped to long term storage from the tank after mixing through a pipe laid across the north end of the adjacent silo and up the side of the nearest above ground slurry store in the adjacent yard. An exterior manual mixing and suction point complete with manhole and safety grid is also be provided on the north side of the tank. The tank is covered with solid slabs with a load bearing capacity of 10 tonne axle weight due to the tank position in the silo yard.

Slurry channel 2 has dimensions of 35.0m long running from Tank 1 underneath the central row of cubicles on west side of the building into the handling pens area. The channel is constructed from prefabricated concrete units 1.0m deep and 1.0m wide provided by Moore Concrete. The channel is covered with conventional cattle gang slats laid end to end. Slurry channel 3 has dimensions of 13.0m long running from Tank 1 outside the north end of the building. The channel is constructed from prefabricated concrete units 1.0m deep and 1.0m wide provided by Moore Concrete. The channel is covered with solid concrete slabs with load bearing capacity of 10 tonne axle weight.

Livestock scraper passage floors

The 2 No. 2.4 m wide passages between cubicle rows and the 2 No. 3.5 m wide passages either side of the central feed passage are finished with grooved concrete ‘sleuf’ flooring similar to the units manufactured by Creagh Concrete and installed between the cubicle rows in the Greenmount Campus dairy unit.

Automatic scraping system

The livestock scraper passage floors are scraped with a ‘finger’ scraper supplied by JOZ, designed to complement the ‘sleuf’ flooring. The floors are scraped from the south end of the building to the north end of the building. The scrapers are pulled by an electrical chain drive system installed outside the north end of the building.

Cattle handling and transport loading facilities

Cattle handling and loading facilities are provided within the building to allow replacement heifers to be routinely weighed, vaccinated, disease tested, anthelmintec and illness treated etc as required for student training, routine husbandry management and technology transfer purposes. The handling facilities provide a safe training environment for student skills training in the above range of procedures. Key handling facilities design features include:

- Circular forcing pen constructed with two number heavy duty gates hinged from a centre post to allow 360 degree movement of each gate around the centre post

- 150mm deep rolled steel plate to be fitted into the curved wall of the forcing pen with barring holes every 500mm for safe movement of heifers to the crush

- The internal width of the race is 650mm

- Two horizontal sliding gates are fitted within the race (one prior to entry of the race and also one prior to entering the second stage of the race

- An automatic self-locking head yoke fitted prior to animals entering the weighbridge crate

- The sides of the forcing pen and the panels between the holding pens and the personnel operating area alongside the race are sheeted with stock board to improve heifer flow through the handling pens

Weighbridge handling crate specification

The weighbridge handling crate has the following specification to allow students to be safely trained in the range of heifer handling practices detailed above:

- Suitable for animals from 150-600 kg

- Weigh crate mounted on electronic weigh bars

- “Scissor” type gate between weighcrate and vet box

- Fitted with ‘squeeze’ type head yoke

- Front cradle/crate to prevent animals escaping past the squeeze head yoke

- Fitted with ‘squeeze’ sides

- Vet access area with gates which access rear of animal from either side

- Top side panels to allow access to upper part of animals body with split gate providing neck access

- Lower side panels

- “Scoop” head restraint

- All steel to be galvanised finish

- Individual prices for additional optional extras to be made available

Sick animal pens

The handling area alongside the holding pens is gated to function both as a race to load animals for transport and also as 2 No. isolation/sick animal pens for heifers receiving veterinary treatment.

Lying accommodation

To optimize productivity and animal welfare in modern dairy heifer housing, the design of the freestall cubicles and lying surface material provides a comfortable environment to encourage heifers to lie in the cubicles. The cubicle design specified allows heifers to readily lie down in cubicles and exhibit natural rising behaviour.

Cubicles

The cubicle is a robust design, suitable for heifers up to 18-20 months of age and provided with adequate adjustment to the brisket board and neck rail to ensure optimal cubicle cleanliness. The dimensions of the cubicles are as follows:

- Cubicle length (solid front) – 2.10 m

- Cubicle bed slope – 2.5 %

- Cubicle division width – 0.98 m centres

- Kerb height (including mattress) – 0.175 m

The cubicle base is constructed from poured concrete with the vertical cubicle supporting posts positioned prior to pouring the concrete base.

Mats/Mattresses

The mattress for the new heifer unit meets the following specification:

- A continuous length to cover a row of up to 32 cubicles spaced at 980mm centres.

- Comfort and shock absorption from functional layers

- Independently performance tested

- 10 year guarantee

Cross passages

Cross passages between the cubicle and feed stance areas are constructed from poured concrete tamp finished with a fall of 1 in 40 from the centre of the cross passage to the cubicle and feed stance passages. Cross passage dimensions are 2.5m x 2.1m.

Feed passage and feed barriers

The feed barriers and feed passages are designed to increase reach and reduce bullying, giving controlled access to feed while facilitating high feed intakes. The feed barrier is a Jourdian “Safety IV model” self-locking safety feed fence mounted above a 450mm x 100mm poured concrete wall. The self-locking safety feed fence allows 75 animals aged 8-20 months to feed at the same time. The locking mechanism for the self-locking yokes has a visible locked position facility from a health and safety perspective.

Feed passage

The feed passage surface within the Cafre heifer rearing unit is raised 100mm above the heifer standing passage to optimize feed intake. The feed passage concrete surface is finished with a wood float finish to provide both a smooth surface for machinery operation and adequate grip for animals crossing the feed passage to the handling pens. The floor surface of the feed passage adjacent to the feed barrier is treated with a 750mm wide strip of epoxy resin paint (approximate cost £10 per m2) continued 150mm from the floor up the feed barrier wall.

Man passes

6 No. man passes are provided into the heifer standing passages, one into each of the 3 sections of cubicle accommodation.

Water troughs

The size and number of water troughs in the building have been designed to meet the DEFRA recommendations:

- Flow rate to water trough of min. 10 litres / minute

- 10% of the heifers able to drink at any given time

- The height of the water trough is 750 mm from the floor with a water level of 50 – 100mm below the edge of the trough

- The water troughs are drained through a 50mm diameter ball valve

Storage area

A gated storage area for feed and bedding is sited in the centre of the building accessed through the handling facilities. The dimensions of the storage area are approximately 6.7m x 6.0m at the widest point.

Stock bull pen

The stock bull pen is located in the south east corner of the building. The main features of the bull pen include:

- Feeding area 4000mm x 2900mm with locking head, heavy duty feed trough and robust recessed water bowl and a raised lying area 3000mm x 2000m with mattress flooring

- Heavy duty 2900mm gate separating the feeding area from the exercise area hinged to close the bull into the feeding area or closing to the service race wall allowing bull access to the feeding area and exercise area

- Exercise area

- Curved wall and railings around the exercise area

- Heavy duty 2900mm gate on ratchet mechanism adjacent to service race. Hinged to force bull to feeding area

- Heavy duty 2900mm gate to force bull from feeding area to exercise area

- Service race 2.4m long fitted with head locking yoke with heifer access from the cubicle pens in the east side of the building

- Bull access to service race via heavy duty 2900mm gate

- Raised personnel standing area, to allow observation of service and allow bull and heifer to be safely separated after service

- Safety features also include a personnel retreat area with access from the feeding area and the exercise area

Lighting

Low energy led lighting is provided to give 200 lumen light intensity in the cubicle accommodation area and bull pen. Light intensity should be 300 lumen in the crush area to allow detailed animal examination.