The Calf Housing Environment

The environmental needs of a calf are fairly simple: physical comfort, good hygiene and reasonable shelter. Modern dairy calf housing should provide such an environment to allow calves to be reared to meet growth rate targets for calving at 24 months of age in a labour efficient and cost effective manner. To meet growth rate targets of 0.85 kg/day throughout the rearing period, it is essential that the calf housing environment is designed to minimise disease incidence and spread in the early stages of calf life.

Calf rearing is relatively straightforward, if calves remain healthy. Key calf house design issues to minimise disease spread include:

- Fresh air (ventilation)

- Air speed (draught prevention)

- Humidity control (drainage)

- Temperature management

How do disease causing micro-organisms spread?

A calf can become infected by disease causing organisms in a number of ways, including:

- Direct contact – calf mouth to mouth – faeces to mouth, mouth to teat to mouth, surfaces to mouth

- Short range air transmission in droplet form – coughing and sneezing

- Airborne diffusion in aerosols – water droplets or dust

What can we do to minimise disease spread?

- Avoid over stocking – 90% of respiratory pathogens come from other calves

- Avoid increasing humidity in the calf environment – ensure good ventilation and good drainage

- Use materials which are easily cleaned e.g. smooth plastic

- Clean and disinfect calf rearing equipment between batches

- Strictly apply veterinary approved vaccination protocols

Stocking density and pen sizes

The minimum recommended air spaces per calf within a building are 6.0m3 for newborn calves and 10.0m3 for 12 week old calves.

Minimum individual pen size should be:

- 1.5m long x 0.75m wide up to 4 weeks

- 1.8m long x 1.0m wide up to 8 weeks

Calves over 8 weeks old should not be individually penned. Calves penned individually must have direct visual and tactile contact with other calves through pen walls.

Minimum space requirements for group reared calves are:

- 1.5m2 per calf up to 150kg (about 4 months old)

- 2.0m2 per calf up to 200kg (about 6 months old)

Calf pens

Where calves are reared in individual pens, the pens should have solid sides made from easily cleaned plastic materials. Pens on wheels or easily dismantled pens that can be taken outside the building for cleaning are recommended.

Group calf hutches

Group calf hutches should: be sufficiently robust to allow mechanical movement for cleaning, be constructed from smooth, easily cleaned materials, have ventilation outlets to allow good vertical air movement and hence ventilation.

Impact of the calf environment on disease transmission

The calf environment affects the survival of infectious micro-organisms in the air or on the surfaces the calf comes into contact with. The environment may also affect the ability of the calf to clear infectious micro-organisms from the respiratory tract and the ability of the calf to mount an immune defence against an acquired infection.

Table 1. Effect of the environment on infectious diseases of the calf respiratory tract. Adapted from: Webster (1984)

| Site of effect | Mechanism | Influential factors |

|---|---|---|

| Pathogen (bacteria, virus, other microbes) | Survival in air | Air temperature, ventilation, relative humidity, dust |

| Survival on surfaces | Surface texture, disinfection | |

| Survival in bedding | Drainage, frequency of bedding change | |

| Pathogen / host (calf) interaction | Transmission (spread) | Stocking density, thermal environment |

| Penetration | Air temperature, relative humidity | |

| Host (calf) | Local clearance from respiratory tract | Air temperature, relative humidity, air pollutants |

| Systemic (immune) response | Stress (thermal, dietary, emotional), other infections |

Concentration of bacteria in the calf house air

Pathogenic micro-organisms are released into the air within a calf house from:

- Infected calves

- Contaminated materials such as bedding

90% of micro-organisms in air come from the calves themselves. Avoiding excessive stocking rates is critical. Stocking densities should not be less than 6.0 m3 per calf prior to weaning.

Reducing concentration of pathogenic micro-organisms

The concentration of micro-organisms in calf house air depends on the balance between the rate of release of micro-organisms into the air and the rate of clearance of micro-organisms from the air. The number of micro-organism colony forming units in a calf house air can range from 1,000 to 500,000 per m3. By contrast the number outdoors is typically <100 per m3.

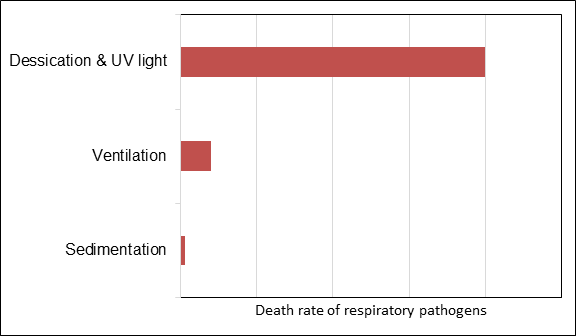

Removal of micro-organisms from air occurs through:

- Micro-organism death through desiccation (drying out) and ultraviolet light

- Ventilation

- Sedimentation (organisms falling to the floor and walls)

The most important clearance mechanism is through the death of micro-organisms while in the air of the building itself. The majority of micro-organisms in the air are present in droplets of water vapour or on particles of dust or skin scales.

Humidity

Micro-organisms die off more quickly when relative humidity is below 80%. However, relative humidity levels may be above 85% during the damp, dark days of winter for long periods.

One of the key functions of good ventilation is to remove water vapour from air, increasing the death rate of micro-organisms, as well as to refresh the air, removing micro-organisms from the calf air space.

Drainage and cleaning

Good drainage is also a critical factor to keep the air as dry as possible and speed up the rate of micro-organism death. Drainage channels should be installed as close as possible to the source of liquids to minimize the area of wet floor surfaces. Falls of at least 1 in 50 should be constructed to ensure rapid drainage of liquids to minimize evaporation and humidity.

Power-hose cleaning produces a lot of water vapour, increasing humidity levels in closed air spaces. Power-hose cleaning of buildings should ideally only be done when the building has been destocked. Equipment such as calf pens should ideally be removed from the building and cleaned outside.

Ventilation

Ventilation of calf housing is critical to minimise the spread of disease and control humidity while avoiding draughts. Ventilation removes heat, moisture, chemical substances and micro-organisms from a building. However, the number of micro-organisms removed by ventilation is considerably smaller than the numbers that die within a building. In winter, the main function of ventilation is to remove moisture from the building and keep relative humidity down, ideally below 80% to reduce the survival time in the air of small aerosols containing micro-organisms.

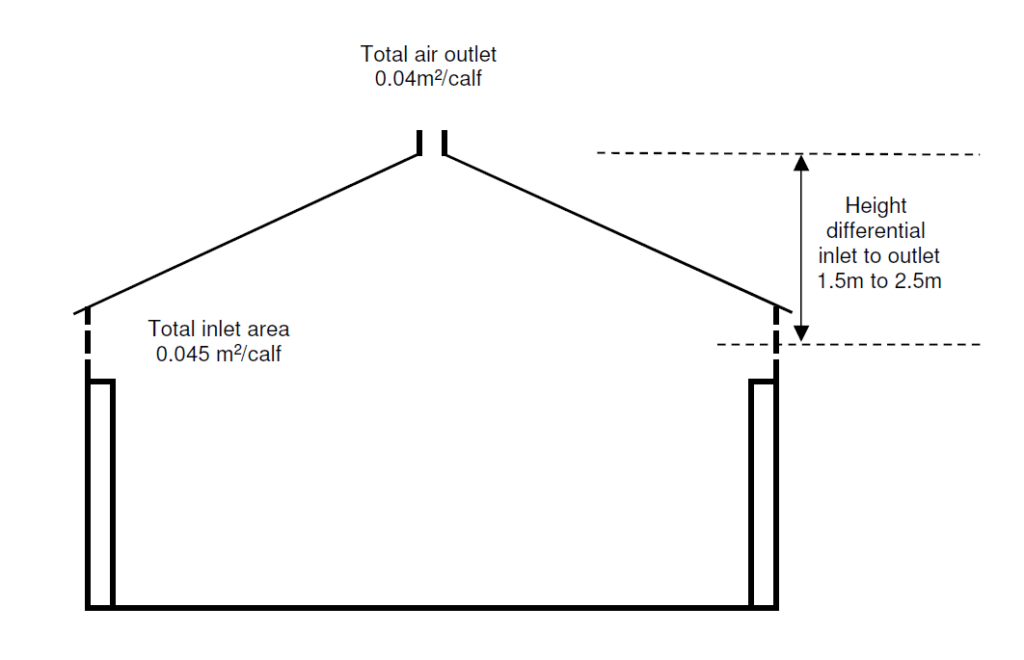

Good ventilation should result in at least 6 air changes per hour in the calf house building. An enclosed calf house should have air inlets of 0.045m2 and air outlet of 0.04m2 per calf. Ideally the height difference between the inlets and outlets should be at least 1.5m and preferably 2.5m depending on the width of the building.

The adequacy and performance of calf house ventilation can be assessed through measuring air space and ventilation inlets and outlets and by the use of smoke emitter pellets of observe air movement within the building. Smoke pellets will also readily indicate where draughts occur.

Draughts

Swedish research has shown a link between calves exposed to draughts and increased incidence of respiratory disease. Air speeds above 0.2 to 0.5 m/s can result in calves becoming chilled and stressed. Draughts are most critical when a calf is housed in an enclosed pen with no opportunity to move away from the draught. Where calves are reared in groups, they may be able to move away from draughts. Deep, dry straw bedding has an important function in allowing a calf to nestle into a bed of straw and protect itself from draughts at floor level. Extra bedding should be provided for young calves when temperatures are below 10oC to allow the calf to nest.

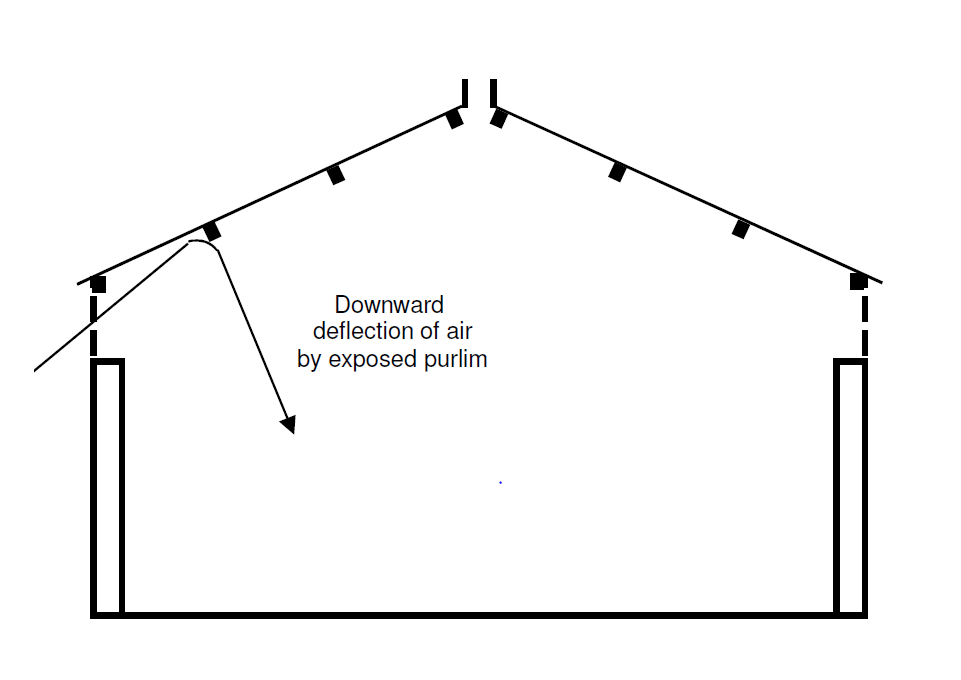

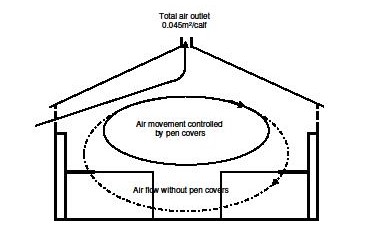

Ventilation should never be compromised to prevent draughts. The impact of draughts may be minimized by:

- providing deep straw bedding to allow the calf to nestle

- installing double row space boarding (Yorkshire cladding) to baffle air inlets

- installing ceiling sheeting over the first 2 purlins to reduce down-draughts

- re-positioning exposed pens to have solid pen sides facing onto draughts

- partially covering the back of pens next to outside walls to reduce down-draughts (but this may increase incidence of pneumonia according to some US research)

Temperature

The newborn calf, sick calves, and calves just transported to the farm are those that are most likely to be affected by low temperatures. The lower critical temperature is the temperature at which the calf starts to feel cold. This does not mean that the calf at this temperature is severely stressed. The lower critical temperature of the newborn calf, after being dried off, but before it has begun to digest and metabolise food is 10 to 12oC. A well fed, healthy calf at 5 weeks of age is unaffected by temperatures close to freezing, provided it is dry and not exposed to draughts.

Table 2. Lower critical temperature of calves (From: Webster, 1984 )

| 0.2 m/s (draught free) | 2.0 m/s | |

|---|---|---|

| Newborn calf | 12oC | 20oC |

| 5 week old calf | 2oC | 11oC |

| 6 month old calf | -6oC | 5oC |

Where calves are exposed to draughts, i.e. air movement speeds above 0.2 m/s, the lower critical temperature at which a calf starts to feel cold increase considerably as indicated in Table 2. The floor or bedding the calf lies on also has a considerable impact on the calf lower critical temperature as shown in Table 3.

Table 3. Floor type and lower critical temperature of newborn calf (From: Webster, 1984)

| Lower critical temperature (oC) | |

|---|---|

| Standing | 11 |

| Lying on concrete | 18 |

| Lying on wooden slats | 11 |

| Lying on damp straw | 11 |

| Lying in deep, dry straw | <6 |

Calf jackets

The benefits of calf jackets have been studied by AFBI, Teagasc and Harper Adams. Teagasc found calf jackets to have no effect on growth rates or calf health. The Harper Adams study found growth rates and disease incidence were reduced. AFBI calf measurements have shown skin temperatures to be raised by up to 5oC when calves are fitted with jackets. Note: to avoid jackets becoming a disease transfer risk, washing and drying equipment needs to be factored in to their use.

Temperature management

Ventilation should never be compromised to raise the temperature of a calf building. The focus needs to be on implementing other measures to keep the calves warm including:

- Providing plentiful quantities of deep, dry bedding in which calves can nest should be a top priority especially in cold weather, as it traps a layer of warm air around the calf, which acts as a heat insulator. The University of Wisconsin have developed a calf nesting score to evaluate the adequacy of bedding. At score 1, calf legs are fully visible; score 2, calf legs partially visible; score 3, calf legs are obscured by bedding. Score 3 should be the target in very cold weather with bedding topped up, particularly at night.

- Calf jackets may help as they can prevent heat loss through convection, conduction, radiation and evaporation.

- Feed intake should be increased in cold temperatures to replace energy being burnt for heat and to prevent growth rates being compromised. AHDB recommend feeding an extra 50g of milk replacer per day for each 5oC drop in temperature below 10oC.