Careful planning required on dairy farms for the months ahead

April 8, 2022

Improving efficiency is a constant challenge on dairy farms. While average milk prices across all processors are currently 6.46ppl higher than February last year, for most farmers this has been off-set by the rising costs of production, particularly when it comes to feed costs and the inputs required to conserve feeds and forages. Conail Keown, College of Agriculture, Food and Rural Enterprise (CAFRE) Senior Dairying Adviser, recognises that “farm fuel has increased by 57% and fertiliser has rocketed by a significant 280%, along with purchased concentrate constantly creeping upwards with no real end in sight. Importantly, we must remember it is the profit margin that we are interested in, while cash-flow on all dairy farms has been significantly impacted with large ‘lumpy’ production costs adding pressure to business bank accounts, controlling and monitoring these costs is critical in the months ahead. Ensuring the efficient use of forage across your system is more important than ever for maintaining your profit margins”.

Improving forage use to offset purchased feed

Now is the time to sit down with your contractor, nutritionist and CAFFE dairying adviser to understand the quantity and quality of silage that will be required for the coming year. Conail says that “many producers are considering reducing chemical fertiliser application in the face of inflated fertiliser prices. This approach will reduce purchased fertiliser cost on your farm, however caution is required as it could also result in forage supply gaps for the winter ahead which will be expensive to fill in terms of purchased forage or expensive purchased concentrate”. Conail advises that “developing a forage plan now will help understand the dairy herd’s feed demand for the months ahead, making more informed decisions around silage making and nutrient planning”.

Decisions around silage making are particularly challenging this year, with many facing a difficult decision as to when to make the first cut, should chemical nitrogen be scaled back, and how many silage cuts should be made? For those that get in early a multi-cut system will achieve a number of cuts of high-quality silage. Those that don’t cut early get the quantity of fewer cuts but not the quality. Co. Down dairy producer Gareth Taylor got in early with his first cut silage last year and was able to make five good quality cuts with an average silage ME of 11.8 MJ/kg DM across all forage made on farm. This enabled Gareth to improve his production from forage and reduce purchased feed cost meaning that he’s holding on to his margins despite the rising cost of production.

The challenge for Gareth this year is the increased cost of making multi-cut silage which is estimated at £35/t DM higher than a three cut system, and while the quality of his forage on a multi-cut system is higher, a three cut silage would reduce the forage making costs for the business this year. This topic was discussed at a Business Development Group (BDG) meeting on the Taylor farm in mid- March with the vast majority of farmers supporting the continuation of multi-cut silage on the Taylor farm this year. Central to the discussion group’s conclusion was the increasing purchased concentrate price. Currently the herd capitalises on the higher quality forage from the multi-cut system on the farm and operates at production performance levels of 10,500l/cow with a feed rate of 0.32kg/l.

Gareth Taylor comments that“quality forage is central to achieving the feed efficiency and milk from forage levels on this farm, the additional cost of the multi-cut system will ultimately reduce purchased feed cost this winter with higher quality home grown forage”.

Complete a fodder budget

Given the stark increase in fertiliser prices coupled with energy price increases, fodder stocks have become more valuable. Getting your forage budget in place early will enable quick decisions on fertiliser applications for first, and subsequent cuts, as you have determined the fodder demand for the winter ahead. The budget also needs to be in place before deciding when to sell cull cows, surplus replacement heifers, and beef stock.

Fodder waste is also an issue and can be as much as 20%. Conail highlights that “we’ve got to cut out any fodder waste to be much more efficient in utilizing our home-grown feeds. Consider all aspects of the forage plan from harvesting and ensiling, through to the feed out phases and ask how much is being wasted. If we can cut waste, we have extra forage to feed to the cows to reduce purchase feeds and become a more efficient milk production unit”.

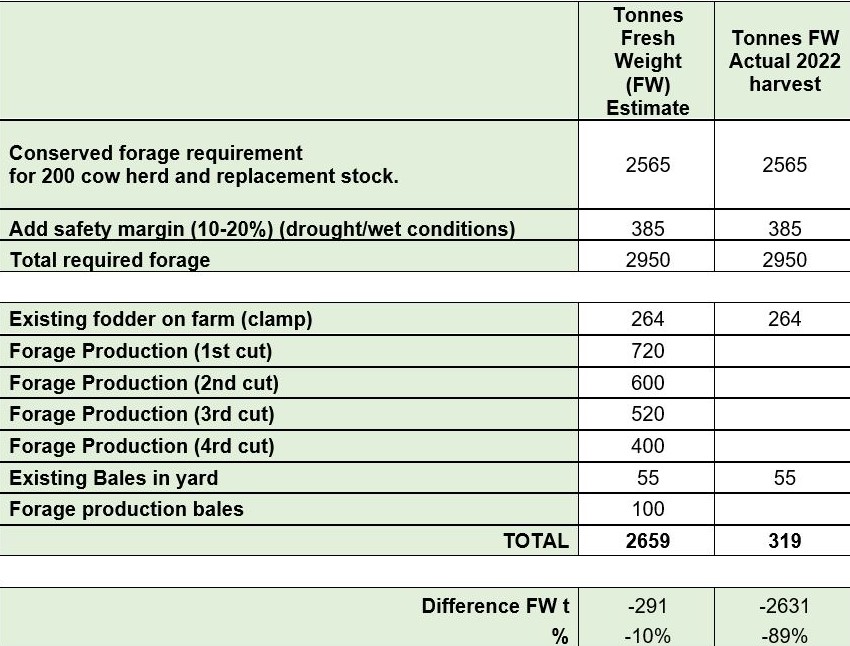

The starting point is to establish the forage requirement for the herd. This can be done in conjunction with the local CAFRE dairy adviser. A table similar to the example given (Table 1) can be generated to track estimated forage production alongside actual forage production as the silage is conserved. In the example in Table 1, the 200 cow herd and replacement stock are estimated to be 10% below target. While this farm has plenty of time to correct this situation, reducing chemical nitrogen is not an option for this farm.

Reducing fertiliser inputs could be counterproductive for Northern Ireland dairy producers. Conail concludes that “even at current prices, it is more cost efficient to grow your own forage than it is to rely on buying it in and key to this is a comprehensive and efficient forage plan”. Every farmer should be calculating their requirements to improve their production from forage. Improving production from either grazed grass or conserved forage will reduce purchase feed cost on the farm and improve margin. Further information is available on the CAFRE website at www.cafre.ac.uk/using-fertilisers-effectively